To construct complex measurement systems, virtual instrumentation combines hardware measurement instruments with programmable software. Virtual instrumentation is frequently used in, for instance, automated testing and measurement facilities, to free the user from having to operate each piece of equipment separately.

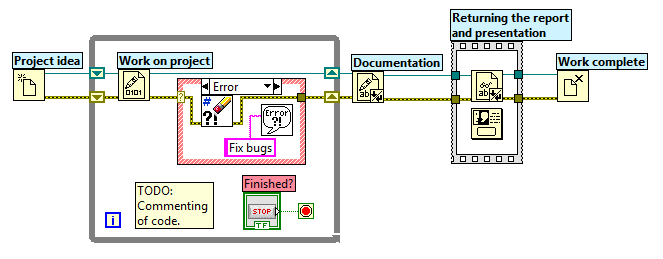

National Instruments Labview, a visual programming language that is frequently used for virtual instrumentation in measurement and testing facilities.